Services

Refining

We are dedicated to transforming precious metals into the purest gold possible, ensuring you receive the maximum value for your assets. We understand the importance of trust and transparency when it comes to refining gold. We utilize advanced refining processes that is meticulous, efficient, and most importantly, delivers the highest possible purity for your gold.

Central to our refining process is our smart version of the aqua regia technique. This chemical method, utilized by most refineries worldwide, has been perfected by our engineers to not only enhance the purity of the gold but also to minimize environmental impact. We are committed to sustainable practices, and our refining process reflects this dedication by meeting pollution reduction and environment protection standards.

Optimizing Smelting Efficiency

The efficiency of smelting processes holds paramount importance in metallurgy. From initial admission to the final output, each step demands meticulous attention to detail. One such critical phase involves sending ingots to the smelting furnace, where fundamental analysis, initiated during first admission, plays a pivotal role. This analysis primarily revolves around determining the ingots' weight and fineness level, laying the groundwork for optimized smelting operations.

Refining

1

The ingots are sent to the smelting furnace after initially assessing their weight and fineness level through fundamental analysis during their first admission.

3

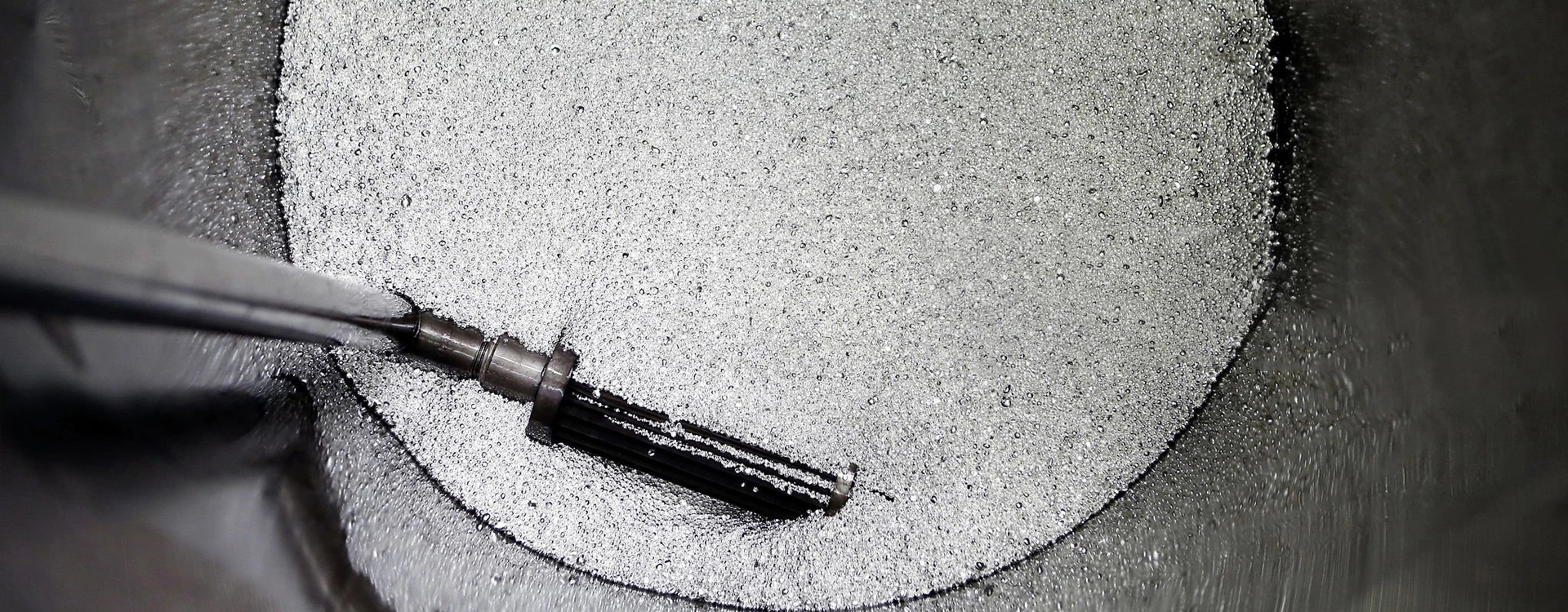

During the refining process, unrefined gold pieces resembling popcorn dissolve in rotary tumblers using a mixture of solvents, employing the Aqua Regia (King's Water) method.

Laboratory Services

Various analysis techniques are employed within the advanced laboratories of Falcon Gold & Precious Metals. Among these methods is 'Gravimetric Analysis,' which entails measuring the mass and concentration of the analyte with a precision scale accurate to six digits. Utilizing the Cupellation method, the gold content within alloyed metals is determined by isolating all metals except silver using lead. Furthermore, through the Acid Parting method, silver is separated from silver-gold alloy using nitric acid, while the residual substances undergo washing, drying, and tempering to extract gold.

At the refinery, instrumental analysis employing a range of devices is conducted. The quantities of valuable metal gold in liquid solutions are assessed utilizing beam and sound through techniques such as ICP-AES (Inductively Coupled Plasma Atomic Emission Spectroscopy) and XRF (X-Ray Fluorescence Spectrometry).